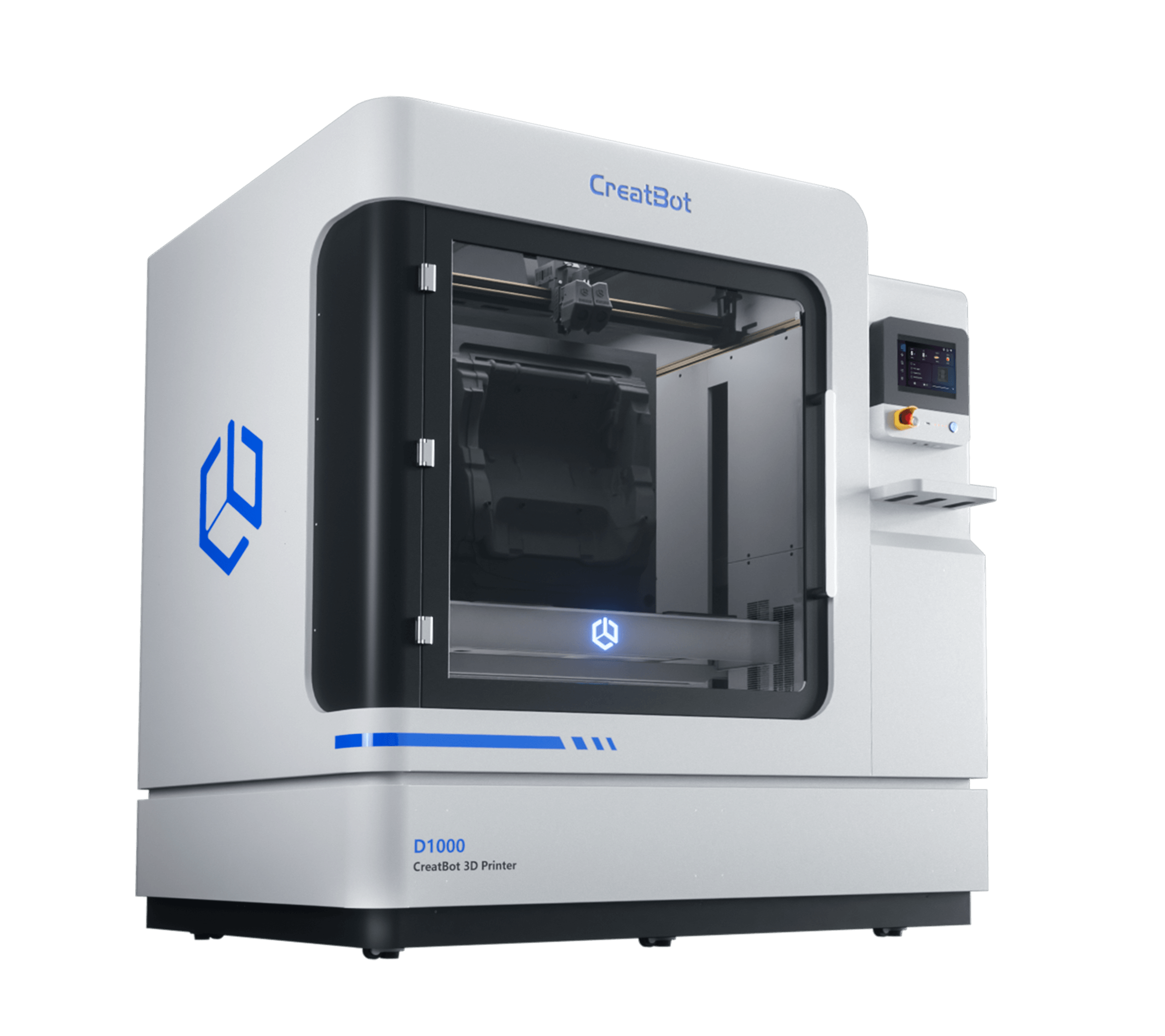

As a 3D printer reviewer we have reviewed many of the A-Lister 3d printers which have gotten the sheer limelight in 2024 and now we are going to review another phenomenal 3d printer, so let’s get directly into the specifications and features of the CreatBot D1000, an industrial-grade large-scale 3D printer that caters to the demands of professionals seeking impressive prints and robust performance. You should also check our previous CreatBot 3d printer reviews and some of the popular ones which provide great quality and value for money. But now, let’s get into the specification details of this mighty great 3d printer that has been considered best of the best for many reasons, few of which have been discussed below:

#1 CreatBot D1000 Specifications

I) Build Volume

The D1000 boasts an enormous build volume of 1000 x 1000 x 1000 mm (approximately one cubic meter). This expansive space allows you to create large, full-size parts, prototypes, tools, molds, jigs, and fixtures in-house.

II) Dual Extruders

Equipped with auto-rising dual extruders, the D1000 can handle a wide range of materials. These extruders can reach a scorching 420°C, enabling you to print not only standard PLA and water-soluble PVA for rapid prototyping but also high-performance materials like ABS, PC, Nylon, Carbon Fiber, and more.

III) Outage Restore & Filament Detection

The printer intelligently memorizes the current position and saves print data during power outages. When power is restored, it continues printing from the last stopped point. The filament detection system halts printing and alerts you when filament runs out, preventing wasted prints.

#2 Linear Rail and Servo Motors

The accurate linear rail structure ensures stability even at the printer’s impressive length. It won’t deform or lose precision after millions of print head movements. Servo motors provide timely, responsive movement without inertia or delay, overcoming the issue of step loss.

#3 Hot Chamber + Filament Dry Room

The enclosed heated chamber maintains a consistent temperature, enhancing print quality and reducing warping. The filament dry room ensures that your filament remains moisture-free, crucial for reliable prints.

#4 Auto Leveling Platform

The D1000 features an auto-leveling platform, simplifying bed calibration and ensuring optimal first layers.

#5 HEPA Air Filter

The built-in HEPA air filter helps keep the printing environment clean by trapping fine particles and fumes.

#6 Key Features

- Industrial-Grade Printing – The CreatBot D1000 is designed for industrial applications, making it suitable for creating functional prototypes, end-use parts, and molds

- Camera Control – Monitor your prints remotely using the camera control feature, which provides real-time visual feedback

- High-Strength Prototype Materials – If you’re tired of fragile PLA and deforming ABS, explore the revolutionary UltraPA-CF material. With a big-size nozzle, you can achieve oversized models with high strength (80MPa) and temperature resistance (up to 150°C)

- Impressive Print Speed – The D1000 can reach a maximum printing speed of 120 mm/s, allowing you to create large-scale objects efficiently

The CreatBot D1000 stands out in the realm of large-scale 3D printers, offering a robust set of features and specifications that make it a top choice for professionals. Let’s compare it to other printers in its class:

- Build Volume – The D1000 boasts an enormous build volume of 1000 x 1000 x 1000 mm (approximately one cubic meter). This puts it in a league of its own, allowing for the creation of large, full-size parts, prototypes, tools, molds, jigs, and fixtures in-house

- Dual Extruders and High-Temperature Capability – The D1000 is equipped with auto-rising dual extruders that can handle a wide range of materials. These extruders can reach a scorching 420°C, enabling you to print not only standard PLA and water-soluble PVA for rapid prototyping but also high-performance materials like ABS, PC, Nylon, Carbon Fiber, and more. This dual-extruder setup allows for versatility and efficient printing of complex models.

#7 Outage Restore & Filament Detection

The printer intelligently memorizes the current position and saves print data during power outages. When power is restored, it continues printing from the last stopped point. So, the filament detection system halts printing and alerts you when filament runs out, preventing wasted prints.

- Linear Rail and Servo Motors – The accurate linear rail structure ensures stability even at the printer’s impressive length. It won’t deform or lose precision after millions of print head movements. Servo motors provide timely, responsive movement without inertia or delay, overcoming the issue of step loss

- Hot Chamber + Filament Dry Room – The enclosed heated chamber maintains a consistent temperature, enhancing print quality and reducing warping. The filament dry room ensures that your filament remains moisture-free, crucial for reliable prints

- Industrial-Grade Printing – The CreatBot D1000 is designed for industrial applications, making it suitable for creating functional prototypes, end-use parts, and molds. It has been adopted by companies like Faurecia, a global automotive system engineering and equipment supplier, for designing and developing automotive seat molds used by brands like Audi, VW, NISSAN, and GM motors

#8 Camera Control

Monitor your prints remotely using the camera control feature, which provides real-time visual feedback¹.

- UltraPA-CF Material – If you’re tired of fragile PLA and deforming ABS, explore the revolutionary UltraPA-CF material. With a big-size nozzle, you can achieve oversized models with high strength (80MPa) and temperature resistance (up to 150°C)

The print duration for a model using the CreatBot D1000 depends on several factors, including the complexity of the design, layer height, infill density, and print speed. Let’s break it down:

- Layer Height – Smaller layer heights (e.g., 0.1 mm) result in finer details but longer print times. Larger layer heights (e.g., 0.3 mm) are faster but may sacrifice some quality. For a standard-quality print, assuming a layer height of 0.2 mm, the time will vary

- Infill Density – Higher infill percentages (e.g., 20% or more) increase print time. Lower infill percentages (e.g., 10%) reduce print time but may affect strength

#9 Print Speed

The D1000 can reach a maximum printing speed of 120 mm/s. Faster speeds reduce print time but may impact surface finish. For intricate models, slower speeds (around 60 mm/s) are recommended.

I) Model Complexity

- Simple geometric shapes will print faster than intricate sculptures or organic designs

- A small, basic cube might take a few hours, while a detailed figurine could take days

II) Material Type

- Different materials have varying print speeds. For example

- PLA prints faster than ABS

- High-temperature materials like Nylon or PC may require slower speeds

#10 Support Structures

- If your model requires supports, the printer will spend additional time creating them

- Consider using tree supports or custom supports to minimize print time

#11 Post-Processing

- After printing, there’s additional time for removing supports, sanding, and finishing

- Complex post-processing can add hours to the overall process

#12 Size of the Model

Larger models take longer to print. A small figurine might take a few hours, while a large architectural model could take days. Given these considerations, a rough estimate for a medium-sized, moderately complex model (e.g., a vase or a mechanical part) with standard settings might be around 12 to 24 hours. However, this can vary significantly based on the specific parameters and design. Remember to adjust settings based on your priorities quality, speed, or a balance of both. Always run a test print to fine-tune settings before committing to a large-scale project.